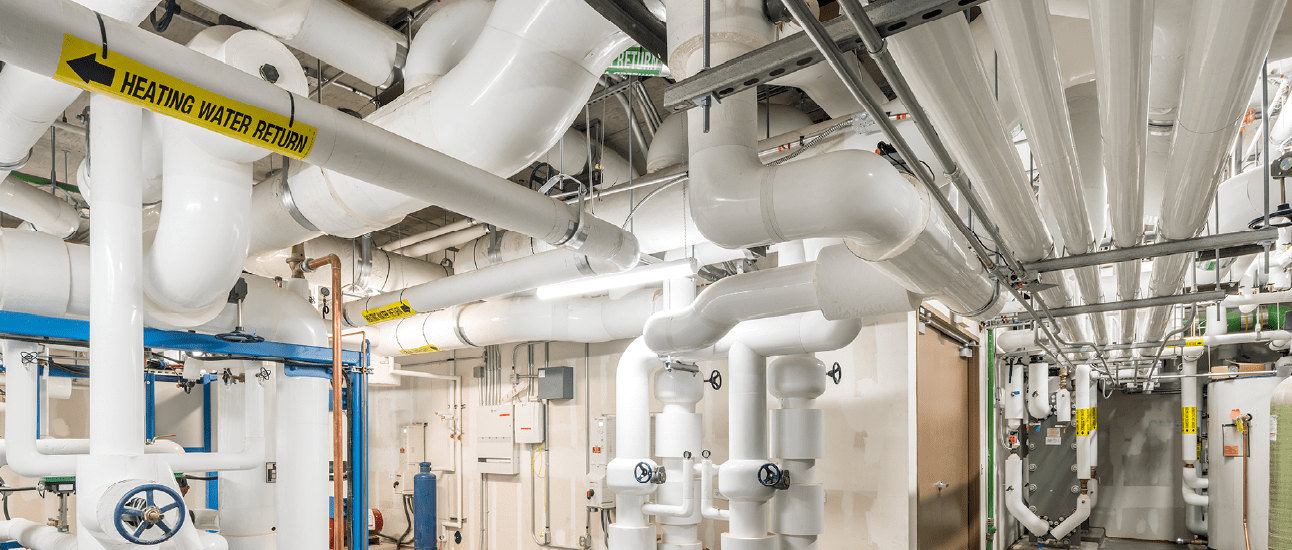

In the realm of construction, safety is paramount, especially when it comes to Mechanical, Electrical, and Plumbing (MEP) systems. These systems are critical to the functionality and comfort of buildings, but they also pose potential hazards if not designed, installed, and maintained according to established MEP safety standards. For more insights on maintaining HVAC systems, check out our HVAC Maintenance Guide for Businesses.

This article explores the key safety standards in MEP, ensuring compliance and outlining best practices that contribute to a safer construction environment.

Understanding MEP Safety Standards

Safety standards for MEP systems are developed by various organizations and regulatory

bodies to ensure the health and safety of workers and occupants. These standards cover a

wide range of aspects, including:

- Design and Installation: Guidelines for the safe design and installation of MEP systems,

focusing on minimizing risks and ensuring that systems are robust and reliable. - Testing and Commissioning: Procedures to verify that MEP systems operate as intended

without posing hazards. - Maintenance: Recommendations for ongoing maintenance and inspections to ensure

that systems remain safe throughout their lifecycle.

Key Safety Standards in MEP

1. National Fire Protection Association (NFPA) Standards

The NFPA sets forth regulations related to fire safety in MEP systems. Key standards

include:

- NFPA 70 (National Electrical Code): This code outlines safe electrical installation

practices to reduce the risk of electrical fires and shocks. - NFPA 13 (Standard for the Installation of Sprinkler Systems): This standard provides

guidelines for fire suppression systems, ensuring that buildings are adequately protected

against fire hazards.

2. Occupational Safety and Health Administration (OSHA) Regulations

OSHA regulations ensure workplace safety for all construction activities, including MEP

installation and maintenance. Compliance with OSHA standards involves:

- Proper training for workers on safety protocols.

- Implementation of Personal Protective Equipment (PPE) such as helmets, gloves, and

goggles. - Regular safety audits and inspections to identify and mitigate risks.

3. American Society of Heating, Refrigerating and Air-Conditioning Engineers

(ASHRAE)

ASHRAE standards focus on the safe design and operation of HVAC systems, emphasizing

energy efficiency and indoor air quality. Important standards include:

- ASHRAE 62.1: Guidelines for ventilation and acceptable indoor air quality.

- ASHRAE 15: Safety standard for refrigeration systems, addressing the safe handling of

refrigerants.

4. International Plumbing Code (IPC)

The IPC provides regulations governing plumbing system design and installation, ensuring

safe and sanitary water supply and waste management. Key aspects include:

- Requirements for backflow prevention to protect water supplies.

- Proper sizing and installation of plumbing fixtures to prevent leaks and overflows.

Best Practices for Ensuring MEP Safety

Providing ongoing training for all personnel involved in the design, installation, and

maintenance of MEP systems is essential. This includes:

- Safety Training: Regular workshops on safety protocols, hazard recognition, and

emergency response. - Certification Programs: Encouraging staff to obtain certifications related to MEP

standards and safety practices.

2. Regular Inspections and Audits

Conducting frequent inspections and safety audits can identify potential hazards before

they escalate. This involves:

- Routine Checks: Scheduled inspections of MEP systems to ensure compliance with

safety standards. - Documentation: Keeping detailed records of inspections, maintenance, and any

corrective actions taken.

3. Implementing Safety Protocols

Establishing clear safety protocols for all MEP-related activities is crucial. This includes:

- Lockout/Tagout Procedures: Ensuring that all equipment is properly shut down and

secured during maintenance to prevent accidental energization. - Emergency Response Plans: Developing and communicating emergency plans for

potential incidents related to MEP systems, including electrical fires and plumbing

failures.

4. Utilizing Technology

Leveraging technology can enhance safety in MEP operations. This may involve:

- Building Information Modeling (BIM): Using BIM to visualize MEP systems during the

design phase to identify potential hazards and conflicts before installation. - Smart Sensors: Implementing smart sensors to monitor system performance and alert

personnel to any irregularities that may pose safety risks.

Conclusion:

Ensuring safety standards in MEP systems is not just a regulatory requirement; it is a

fundamental aspect of responsible construction management. By adhering to established

safety standards, providing ongoing training, conducting regular inspections, and

implementing best practices, construction companies can mitigate risks and ensure a safe

working environment. Prioritizing safety not only protects workers but also enhances the

overall reliability and performance of MEP systems, contributing to the success of

construction projects and the well-being of building occupants.